Does your fire protection equipment have corrosion? Not sure? It’s important to understand how fire sprinkler corrosion control and mitigation can impact your bottom line and what you can do about it. During the past year, corrosion control – specifically for air vents on wet fire sprinkler systems – has been a hot topic in the fire protection industry due to more jurisdictions adopting the 2016 edition of NFPA 13: Standard for the Installation of Sprinkler Systems, which includes the requirement to install a means of venting on any wet system that uses metallic pipe (7.1.5).

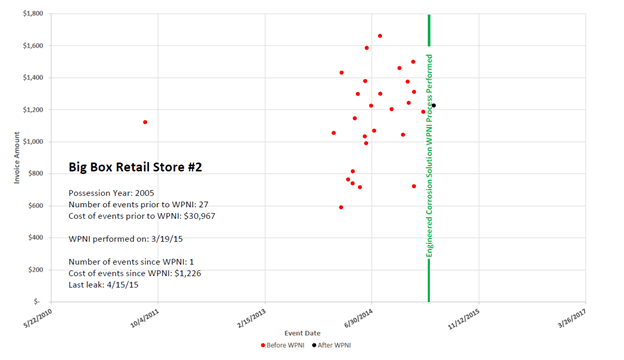

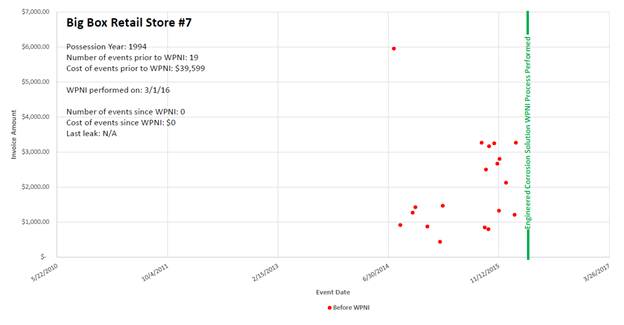

If your business struggles with leaks or corrosion in fire sprinkler systems or other fire protection systems, be sure to read the following case study. It shows how the adoption of NFPA 13 and the implementation of air vents to control corrosion on wet fire sprinkler systems worked in nationwide, multi-site big box stores to significantly lower the number of leak events caused by corrosion. You will see how, in one store, leak events plummeted from 27 at a cost of $30,967 to a single event with the cost of $1,221. In another store, the dramatic outcome of corrosion control resulted in zero leak frequency at a cost savings of $39,599.

Proactive Fire Sprinkler Corrosion Control Program: 4700 Big Box Retail Stores

As the use of air vents on wet fire protection systems becomes ubiquitous, it is worth noting that several big box retail stores were ahead of the industry. In 2008, the first major retail chain adopted the use of air vents on new construction to mitigate oxygen corrosion in their wet fire sprinkler systems.

In 2013, a joint venture between Alternatives in Engineering and Engineered Corrosion Solutions began the ambitious task of evaluating a property portfolio of 4,700 retail store locations to develop a fire-equipment and fire-sprinkler corrosion control program that would shift each facility’s maintenance procedures from reactive to proactive, while drastically reducing the amount of operating budget that was spent on fire sprinkler system leak repairs.

In 2013, a joint venture between Alternatives in Engineering and Engineered Corrosion Solutions began the ambitious task of evaluating a property portfolio of 4,700 retail store locations to develop a fire-equipment and fire-sprinkler corrosion control program that would shift each facility’s maintenance procedures from reactive to proactive, while drastically reducing the amount of operating budget that was spent on fire sprinkler system leak repairs.

In analyzing the data, it was determined that less than 5% of store locations were responsible for over 80% of the total spend for fire sprinkler leak repairs.

Corrosion Mitigation Solution with Dramatic Results: Near Zero-Leak Frequency

Immediately, a plan was developed to use Wet Pipe Nitrogen Inerting (WPNI) in conjunction with surgical pipe replacement on the worst 20 stores. The plan and corrosion mitigation solutions were deployed over twelve months to the identified locations with dramatic results, which are represented in the charts below.

The combination of WPNI and limited pipe replacement reduced the leak frequency to near zero. Over the next two years, an additional 40 locations had the WPNI procedure performed with similar results.

The Next Step in Corrosion Control: Vent Automating to Remove Human Intervention

During the initial research phase, it was identified that the store remodeling process was a precursor to a significant increase in sprinkler system leaks. The reason for this is that the remodeling work is performed at night with the store returning to operations the following day. This required the sprinkler systems to be drained each night and refilled each morning for the duration of the remodeling project. The repetitive drain/fill process introduced large amounts of oxygen into the pipe network daily. The trapped oxygen was immediately able to react with the sprinkler pipe and aggressively remove metal, leading to corrosion in fire sprinkler systems.

With this fire sprinkler corrosion in mind, and on the tail of great success performing the WPNI process, the next step in corrosion control was to require the installation of a wet system air release vent on any system that was subject to the remodel program. When writing the remodel specifications, the design team had to determine which vents would be allowed to satisfy their design intent. NFPA 13 leaves the requirement for air vents on sprinkler systems very open – anything from a manual vent (minimum ½”) to an automatic vent is allowed. There is even a provision that would allow “other approved means.”

Taking the requirements of NFPA 13 under advisement, the design team decided to use an automatic vent to remove the dependency on human intervention. The design team then went further to require a vent that could provide a redundant function to minimize the chance of fire sprinkler pipe corrosion or creating a slipping hazard on the floor.

While assessing vent types, single float vents were evaluated, but while less expensive than redundant vents, they were not chosen because they require their outlet to be plumbed to drain into water sensitive areas, and that extra cost makes a single vent more expensive to install than a redundant float vent. Therefore, redundant automatic air vents were chosen.

Several years into the remodeling program, it was clear that installing redundant automatic air vents on the sprinkler systems had significantly reduced fire sprinkler head corrosion-related leaks.

Air Vents Stop Corrosion in Fire Sprinkler Systems & Increase Longevity

Installing redundant float automatic air vents on any wet fire sprinkler system is one of the best corrosion mitigation techniques to stop leaks. These vents also increase the longevity of the sprinkler pipe and useful life of the entire system, resulting in lower operational, repair, and equipment costs and more reliable fire protection.

If you would like more information about air vents that stop fire sprinkler pipe corrosion-related leaks in your multi-site retail stores, big box stores, distribution centers, grocery stores, or warehouses, or wish to discuss your specific fire protection needs, please contact AIE at 800-892-9863. We have many fire sprinkler corrosion control and mitigation technologies and solutions.

About the Author

Adam Hilton, President & COO, Engineered Corrosion Solutions

Adam Hilton has practiced in the fire protection industry for 15 years with experience in fire protection and alarm systems design, code compliance, corrosion assessment, and consultation, as well as product research and development. Mr. Hilton received his B.S. in Electrical Engineering from Missouri University of Science & Technology. He is currently the President and Chief Operating Officer at Engineered Corrosion Solutions, LLC. Mr. Hilton is a member of the Society of Fire Protection Engineers and the National Fire Protection Association.

Recent Comments